Une gamme de convoyeurs et d'équipements pour le Packaging

ACCS PACKAGING : entreprise d'ingénierie

Développeur de solutions en Packaging

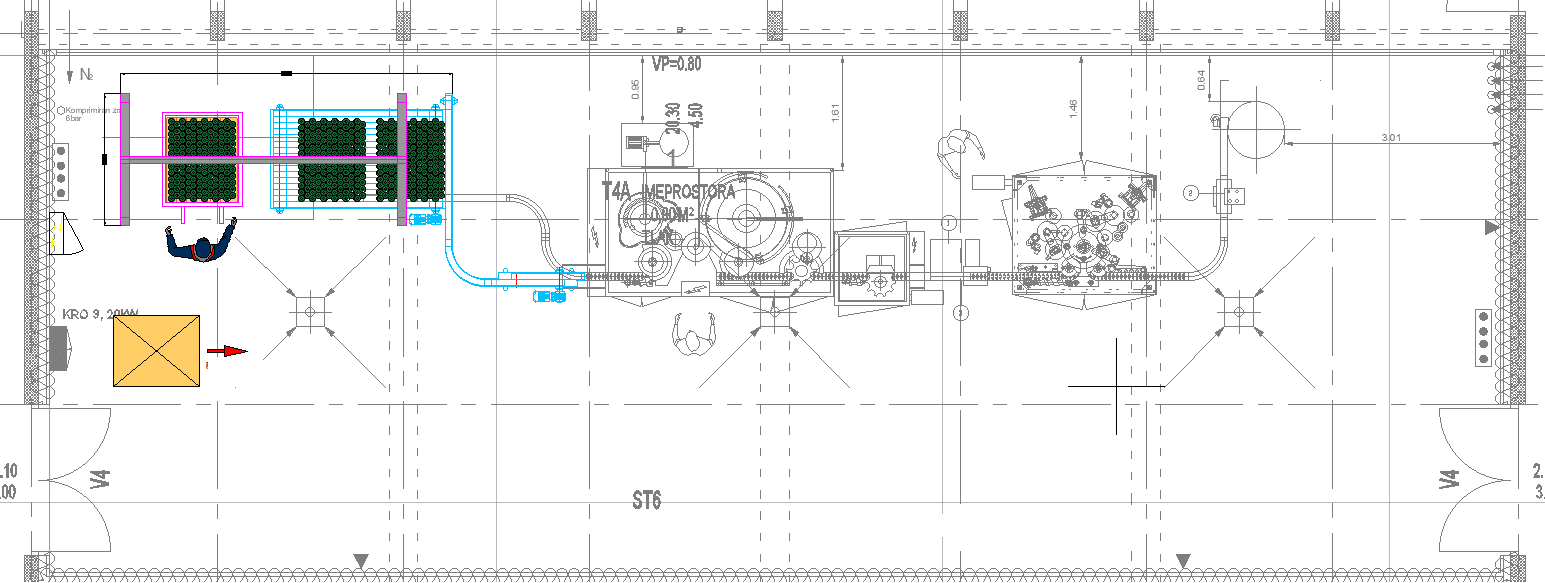

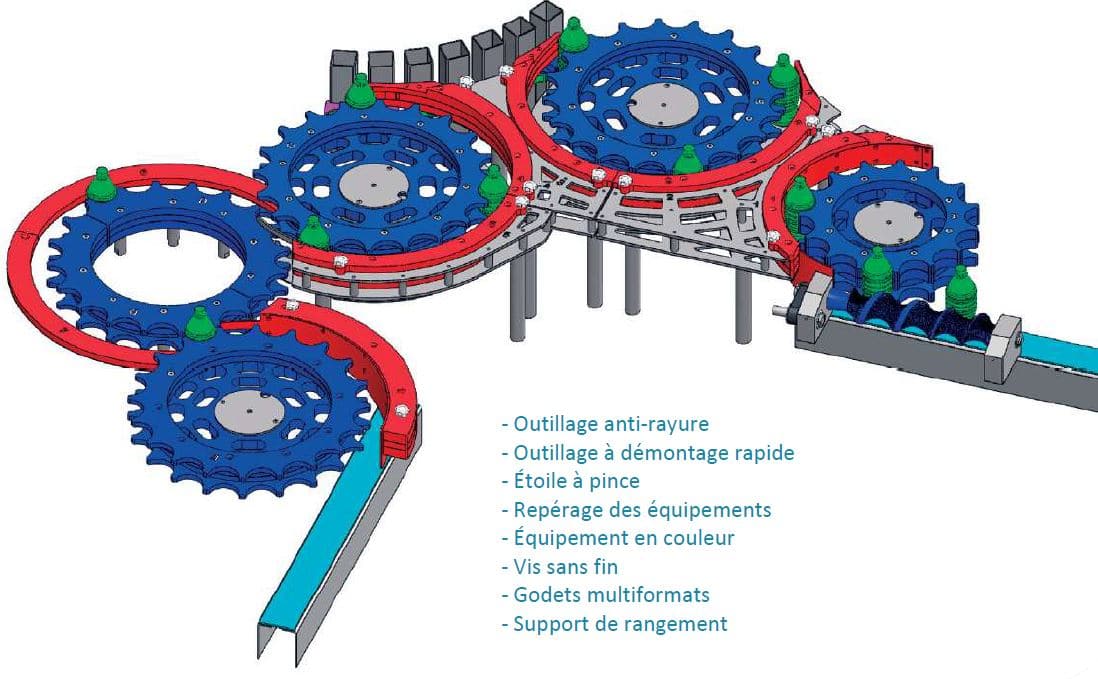

ACCS propose une gamme étendu de convoyeurs et d’équipements pour un meilleur transfert de vos produits emballés. Nous fabriquons et intégrons des solutions adaptées à presque tous vos besoins. Nous proposons également des services d’ingénierie et de conseils pour vos projets de nouvelles usines. Nous vous accompagnons du début de votre projet jusqu’à la mise en route de votre ligne.

- Les convoyeurs à air (pour bouteilles, bouchons et canettes)

- Les convoyeurs mécaniques

- Les convoyeurs de fardeaux

- Les convoyeurs de palettes

- Dépalettiseur

- Palettiseur

- Robot collaboratif

- Conseil en ingénierie de ligne par un expert

- Suivi des travaux

- Montage/câblage et mise en services

Nos solutions mises en oeuvre

Services associés

Etudes et Services

En savoir plus

Chaque projet fait l’objet d’une étude spécifique. Un chargé d’affaire coordonne les études mécaniques et automatismes ainsi que l’organisation des chantiers jusqu’à la mise en service.

Innovation

En savoir plus

ACCS Packaging consacre une part importante de son budget à l’innovation afin de répondre au plus juste aux exigences du marché et de ses clients.

Partenariats

En savoir plus

ACCS Packaging est partenaire avec plusieurs sociétés à travers le monde Argentine, USA, Liban, Arabie Saoudite, Brésil.

Automatisme

En savoir plus

ACCS Packaging est très exigeant sur la qualité du matériel ainsi que les programmes mis en place pour automatiser ses équipements.

Services sur site

En savoir plus

ACCS Packaging assure le montage et la mise en service de ses équipements.

Maintenance / SAV

En savoir plus

Grace à la mise en place d’un catalogue et d’un outil de gestion dédié, ACCS Packaging est en mesure de répondre rapidement aux attentes des usines en termes de pièces de rechanges.

Votre projet commence ici !

ACCS PACKAGING

771 Allée de la Baraquette

30390 DOMAZAN

France

Horaires

Du lundi au vendredi : 9h00-18h00

Téléphone

(+33) (0)4 66 01 37 48